Full Review with Rob Ruscoe

Kit ref: 48320

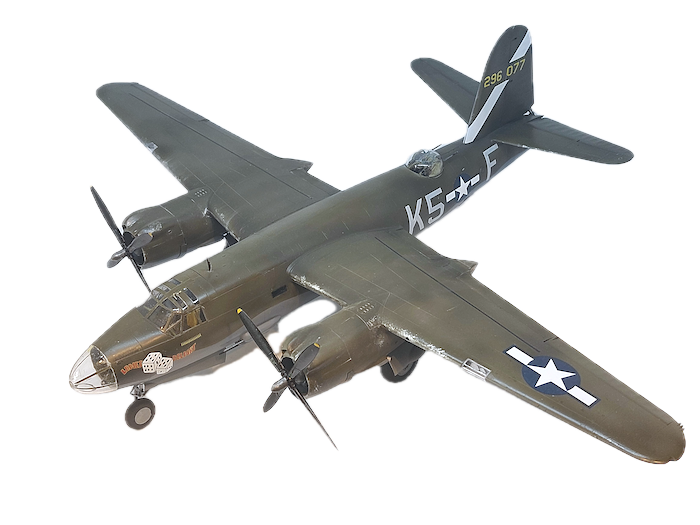

Just before we get started, here’s a look at how it all turned out…

In March 1939, the USAAC issued a requirement for a twin-engine medium bomber with a maximum speed of 350mph, a range of 3000 miles and a bomb load of 2000lb. The Glenn L Martin Company was quick off the mark and three months later submitted its design, the Martin Model 179. Martin’s design was judged superior to other proposals and was awarded a contract for 201 aircraft to be designated B-26. A further order for 930 B-26s followed in September 1940 – still two months before the first flight. To meet the speed requirement, great attention was paid to streamlining with a circular-section fuselage attached to a wing which had, for the period, a high wing loading of 53lb/sq ft.

This relatively small wing resulted in a high landing speed of 120 to 135mph depending on load. The safety speed on take-off was also on a par with the British Mosquito but although the Pratt & Whitney R-2800s were as reliable as the Mossie’s Merlins, the Curtiss electric propellers fitted to the B-26 were not. These props suffered from failures which placed the blades in full fine pitch causing over-speeding and loss of thrust. This was more likely to happen at high power settings on take-off.

This combination of high safety speed and loss of power led to a large number of accidents after the aircraft entered service, resulting in the Marauder gaining a number of uncomplimentary nicknames such as The Martin Murderer, Widowmaker, Flying Coffin and The Flying Prostitute; the latter referring to the small wings giving the aircraft no visible means of support!

With the B model, Martin gave the Marauder an extra six feet of wingspan and increased the incidence to give a better take-off performance and although the aircraft remained challenging to fly it eventually achieved the lowest combat loss rate of any American bomber. The B-26 served in both the Pacific and European theatres not only with the USAAF but also with the Royal Air Force and the South African Air Force. Altogether 5288 Marauders were produced of which seven are known to have survived. Only one of these is nominally in airworthy condition with Kermit Weeks in Florida although this aircraft has not flown for a while.

The Kit

The kit arrived packed in ICM’s usual sturdy packaging with some nice box art on the top. The large box was full to the brim with eight large sprues of styrene, a clear sprue, a PE fret and a decal sheet containing markings for three aircraft. The instruction booklet is in ICM’s usual style with a logical build sequence but can be a little vague in the positioning of smaller parts at some stages. Dry-fitting resolves this issue. A comprehensive painting matrix is included on the front cover but does not relate to any manufacturers as such. The parts are cleanly moulded with nicely recessed panel lines and detail. There are a number of holes to drill in the airframe and these can be easily missed. For that reason I elected to drill all these in one go before starting construction. There are no alternative parts and so choice of markings can be left until the airframe is complete. There are, however, two different canopies and nose transparencies included on the clear sprue which are marked as not to be used. I assume these are for the later G model which is obviously in the pipeline.

Paul Ainsworth says

“Hello,Rob” – An excellent feature and build of the Marauder.

I’ve heard good reports about ICM kits and you’ve certainly done justice to this one.

I love the finishing-work.The tonal variation,weathering and chipping-effects really bring her to life.

A model to be very proud of.🏆

As Always,

Paul.😉👍

Rob Ruscoe says

Thanks Paul.

Much appreciated.

ICM are certainly up there with the top manufacturers. They also keep Revell going!

Rob.R

Tim English says

Very nice work, your paint work looks fantastic.

I built a 1/72 Airfix Marauder a few years back & had the same problem with the gear strength & can imagine it being worse with a 1/48 scale one.

One idea to add strength is to add a thin piece of wire connecting the gap beween the tire & the gear strut, or possibly clear sprue so that it is hardly visible.

The angle forward on the leg doesn’t help matters either!

Rob Ruscoe says

Thanks for your nice comments Tim. Makes the effort worthwhile. I build OOB for the SMN articles warts and all. I can report the main legs on the Marauder have been drilled and pinned already. Replacement white metal legs are the only long term answer though. With any model like this, I think the manufacturer should already include metal landing gear as standard. Trumpeter were guilty of this in the past but they have listened to the criticism and provided metal legs in their heavier kits. Hopefully ICM and others will take note.

Regards

Rob.R