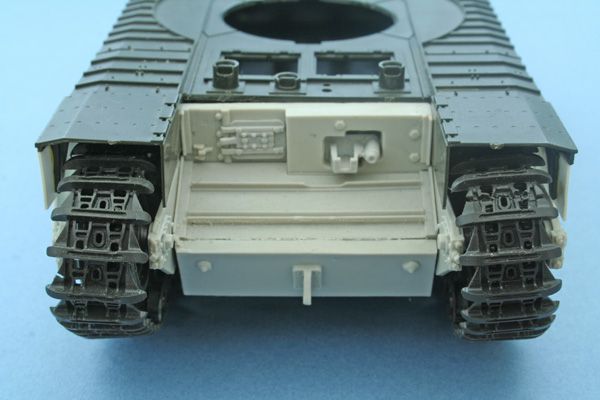

The front hull parts are straight replacements for the kit parts

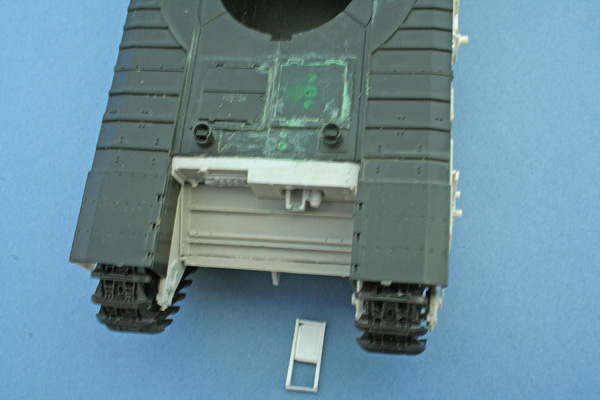

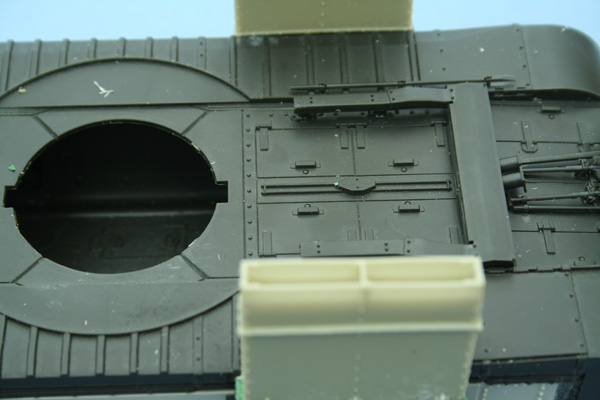

The middle periscope was removed and the driver’s hatch put in place. The tank was armed with a Spigot mortar firing a demolition charge which was loaded from inside the tank via a sliding hatch replacing the hatch for the hull gunner. The kit hatch was reversed to fill the gap and the new hatch glued into place.

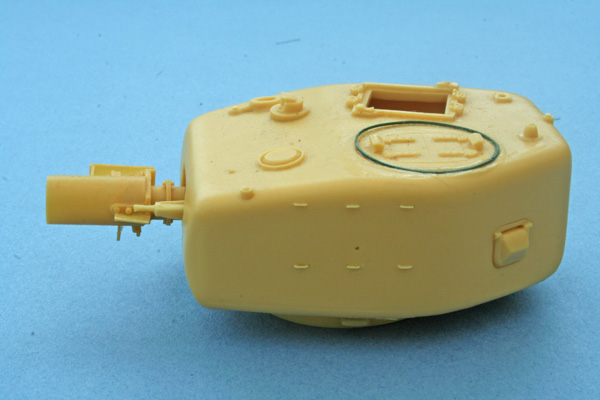

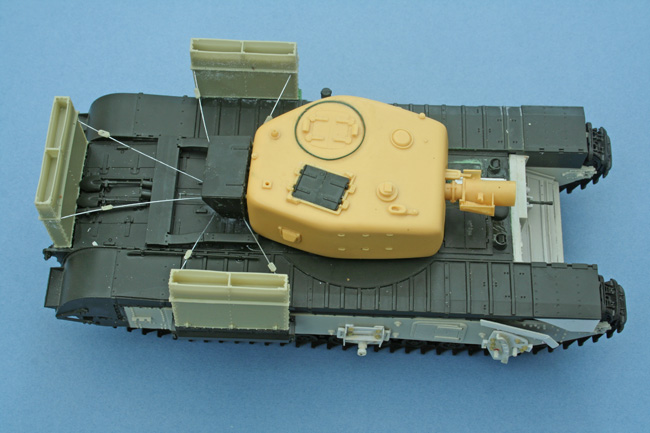

The KK Casting turret was a straightforward assembly. It is important to cut off the locating lugs as with the deep wading vents in place the turret cannot be fitted.

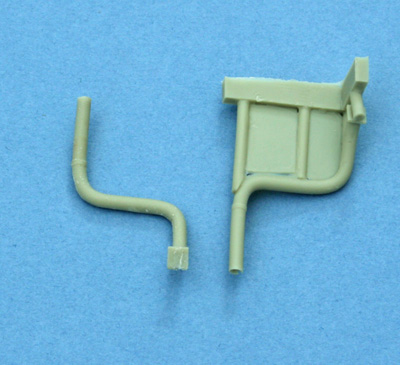

As with all resin parts the casting blocks and supports must be carefully removed to leave the casting on the left.

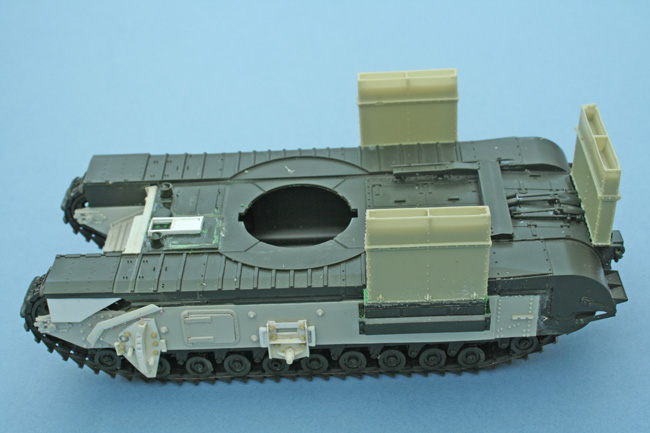

Fitting the Resicast deep wading equipment aligned well with the kit parts.

The exhaust and intake pipes and vents need braces which were cut from garden wire. This was the most difficult part of the build as if not straight the brace does not look convincing..