More mods

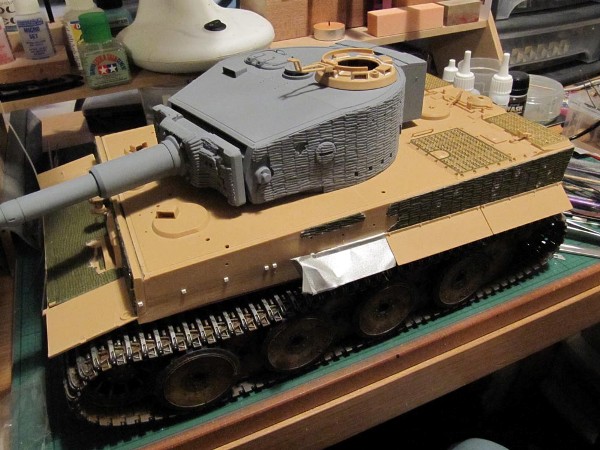

On the rear bulkhead, which is screwed in place into the chassis, the flexible zimmerit had been fitted, which, given the number of parts to be fitted to it, caused quite a headache. Wherever a jack, or mudguard was to be fitted, a space for the attachment lug had to be chiselled out. The end result looks reasonable though, and it was nice to get a coat of undercoat onto it, to get an idea of the finish.

The turret was undercoated too, the cupola, as can be seen, was not finished, but may need to be left off, for a figure to be fitted inside the hatch. Not too sure about this bit yet!

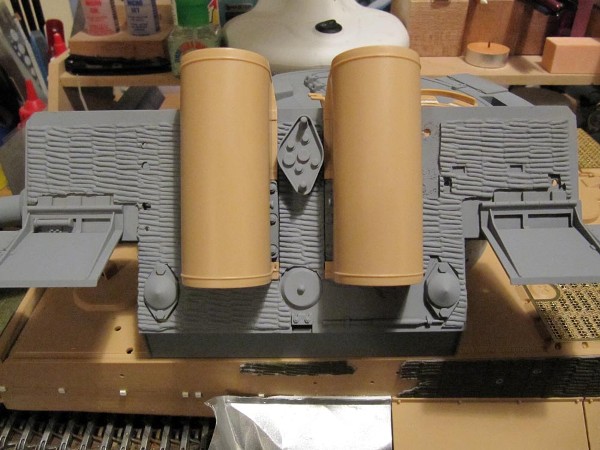

The exhaust shields need to be ‘distressed’, but fit well.

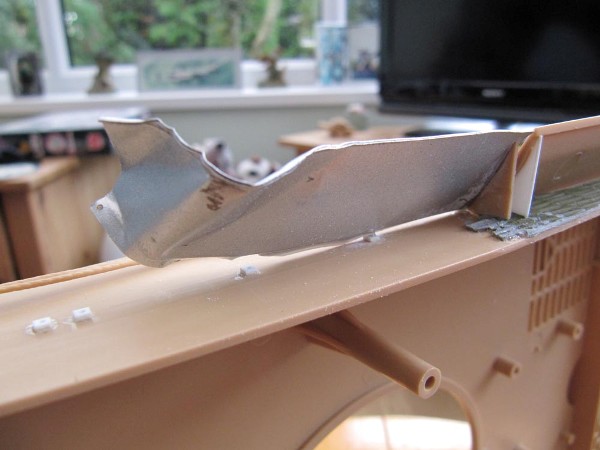

The track guards had been removed previously, and a replacement crafted out of aluminium window blind; it was to be partially ripped away. Window blind material was used, but as the cross section of the blind was slightly curved and too thin, two pieces were taped together using double-sided tape, giving the right thickness, and getting rid of the problem curved section.

The track guards had been removed previously, and a replacement crafted out of aluminium window blind; it was to be partially ripped away. Window blind material was used, but as the cross section of the blind was slightly curved and too thin, two pieces were taped together using double-sided tape, giving the right thickness, and getting rid of the problem curved section.

The resulting guard was then shaped correctly, drilled for the fixing bolts, and then buckled. The fillets were fitted under the guards at the end of each section too.

Getting down to some of the smaller items, the cable clamps / cleaning rods, although reasonable, had to be modified as I intended using steel tow cables. The end of the tow cables were retained as they looked quite good, but the retaining clamps on one were cleaned up and drilled out to improve the look of it.

The other cable had the clamp removed as it was to be attached to the shackles at the front and back of the tank. Instead of making new rod/cable retaining clamps, I decided to use the existing moulded items.

The clamps were cut from the cables and rods and cleaned up ready for marking out. Five hole centres were marked on the clamps, three for rods and two for cables, and initially drilled with a 1mm drill, then again with a two mm drill, and finally with the finishing diameter. They were then cleaned up, ready to try the new cleaning rods for size.

The new cleaning rods were made from Kebab sticks, which were cleaned up and the diameter reduced with glass paper until down to size, then cut to length. The ends were drilled to accept a piece of guitar string, which looks just like threaded rod when fitted.