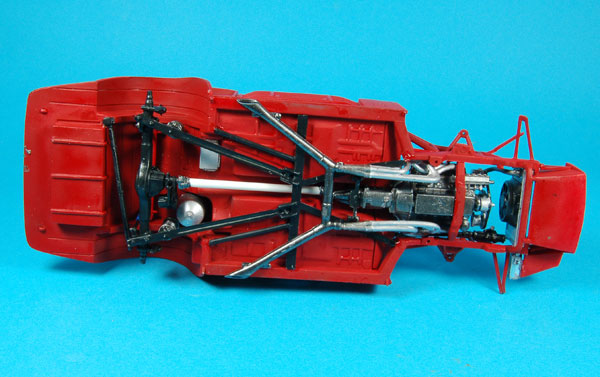

Chassis and suspension

The chassis and its corresponding suspension parts were the next to be assembled. The separate parts having been assembled and painted first.

It was at this point that things started to start going a little wrong. Parts not lining up and assemblies falling off. In fact, if it could go wrong, it did. Frustration soon followed by shall we say non-modelling related language. Instead of putting the model down and taking a break, I foolishly pushed on.

Now in NASCAR, like any other motorsport, there are crashes. Some of these in NASCAR are a result of the car hitting the outer wall. More often than not, totally destroying the car. Why am I telling you this? Because the next thing to happen was my NASCAR hit the wall!

Yes, I lost my temper with a bit of plastic and paint and threw the damn thing at the wall. “Race over” I hear you say? Well maybe not, as I picked up the pieces and did what I should have done an hour before and put the whole lot back in the box. A couple of days later I arranged to give the parts to a modelling friend and placed the kit in its box ready to picked up when I next went to see him.

However, every time I walked past the box I could hear it taunting me. “I beat you”. “A bit of plastic won”. “Some modeller you are”. After two weeks of this I relented, picked up the box and put it back in the modelling bench.

NASCAR resurrection

First thing to do was to make sure I had all the parts and make repairs. The floor pan, roll cage and chassis had hit the wall with some considerable force. Fortunately there was nothing more damaged than a couple of loose parts on the roll cage and the chassis had separated from the floor pan.

So once again the build was started and again there was frustration and a bit of non-modelling like language, but the model was put down and tea drunk. Slowly over the course of a day, the chassis finally mated to the floor pan.

Next was to install the engine and drive shaft. This went together relatively easy with only the drive shaft that needed to be trimmed to make it fit. A fault of the kit or me? More than likely the latter.

The finishing touches

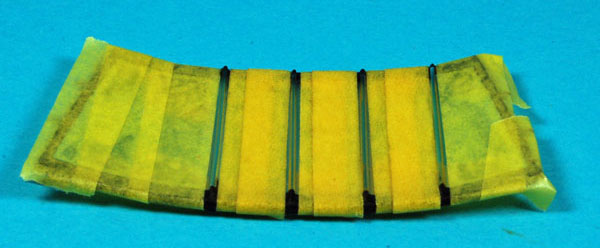

There remained one last part to finish off. On the underside of the car, the exhaust system needed to be connected to the down pipes/headers. The next job was to carefully put the body onto the floor pan assembly. The whole operation went well and firmly snapped into position. Just two more stages now remained. Masking the windshield and side windows so that the edges and protection bars that stop debris smashing through the screen could be sprayed black.

Once dry, they were unmasked and the clear parts fitted to the body. The last stage was to fit the wheels and tyres to the car.