Decals

with Geoff Coughlin (March 2020)

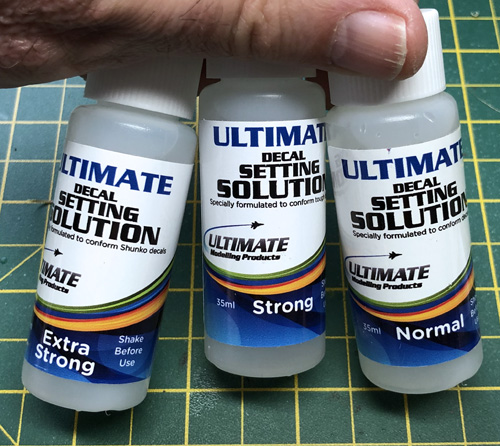

New products are always coming along and the availability of decal softening and setting solutions is also growing. Here we have three new products from Ultimate Modelling Products designed for applying your decals and the aim is to help them appear as if your markings have been sprayed on.

We are talking waterslide decals in this review/demo – the markings that you need to float off their backing paper and apply to your models. These solutions are therefore designed to work with these types of decals.

Three strengths of Ultimate Decal Solution are available:

- Normal

- Strong

- Extra Strong

Why 3 different strengths?

Basically the more models you build and the more decals you work with from the different kit manufacturers it becomes clear very quickly that not all decals are the same and not all decals are the same quality. Far from it, although in my experience, the quality of decal sheets being provided in new kits these days is much improved and that’s great to see.

The differences come in many forms and the main thing to look for (after quality etc) is the thickness of the carrier film. Gently run your thumb or finger of the decals and notice how significant the ridge or stem is between decals? Waterslide decals are printed onto a carrier film that has glue impregnated into it so that when you float your decal on some warm water the backing paper takes up the water and when you look at the top of the paper, it starts to look damp and wet. You can remove the whole thing from the water and then slide your decal into position on your model.

The problems commonly encountered…

Some manufacturer’s decals can be quite thick and when you apply them to your model and allow your decal to dry, it can sometimes not adhere convincingly to the model surface detail – raised or recessed. This is really frustrating and can ruin the look of your model and leave your markings looking toy-like and unrealistic – not good! The usual end result is that you get a silvering of the carrier film, making it visible and the aim is to make it invisible – this is crucial to successful decal application. This ‘silvering’ is caused by air getting trapped under the decal and any air at all will create this silvering that is hard to eliminate later, so we need to just avoid it happening in the first place and that’s usually very easy to do – read on…

The purpose of these decal softening-setting solutions…

The purpose of all these decal softening and setting solutions is to soften the decal at the time of application and so, when it dries the solution draws the decal down over any raised detail and into recessed details like panel lines and hatches etc. The end result is a much more convincing marking that will look like it’s been painted on, just like the real thing on whatever subject you are modelling.

Ask a question or add feedback:

You must be logged in to post a comment.